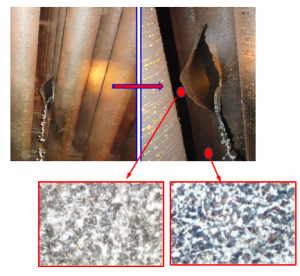

Failure analysis had been conducted on an oil heater in a Refinery Plant. One of 6” OD tubes heater bulged and ruptured due to creep (high temperature deformation). Upon analysis it was found that the cause of failure is due to fire impingement on that tube causing a short term over heat (hot spot) and thus rupture.

Further investigation revealed that the fire was caused by oil leak occured on the other tubes that generated flame intensity exceeding design specification. Metallography analysis shown the different microstructures in the tube location at the rupture zone, and other location away from it, affected by different heat intensity. It is turned out that the root cause of failure was due external corrosion on the other tubes that leaking.