Reliability centred maintenance (RCM) is commonly conducted in process plants to generate the best maintenance strategy in the form of a detail inspection and test plan (ITP), or so called a task list, for each particular equipment including static, rotating and electrical equipment, and instrument and safety critical equipment, and so the reliability and availability of the facility is improved and unplanned shutdown can be reduced or prevented.

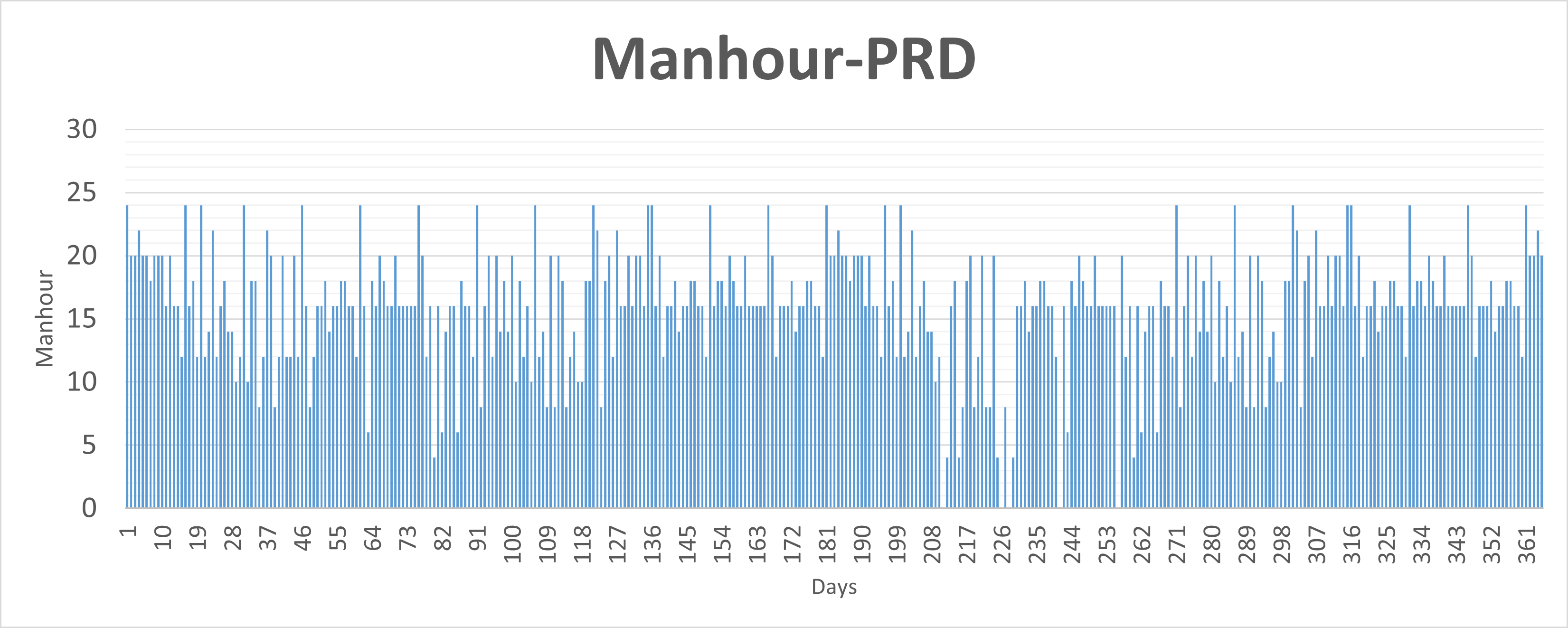

However, to further utilize the benefit of RCM, the result may also be used to provide job bundling and levelling,meaning that all resources (time, man power, budget), for maintenance activities throughout one year period or more, can effectively be managed. Furthermore, the RCM results can also be used to determine the critical spare parts management. By using a specific methodology, material procurement and inventory in the warehouse could be managed more cost effectively.